At Hindustan Zinc, we have added one more 'R' to the waste hierarchy - 'revenue' from waste. While we continue to reduce, recycle, reuse, and dispose the waste in an environment friendly manner, we are going a step ahead to generate value out of the waste.

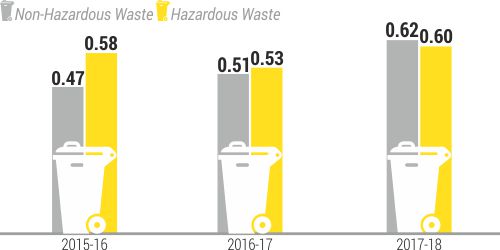

The major wastes generated by our operations are tailings, jarosite, slag and rock. All wastes are stored at earmarked places and hazardous waste is disposed timeously through approved registered recyclers as per the Hazardous Waste Rule. We have laid down comprehensive guidelines on waste management, which cover hazardous as well as non-hazardous waste and monitoring of waste management is carried out on a regular basis.

During the year, a Waste to Wealth Committee was constituted to spearhead waste reduction and value extraction initiatives. Several initiatives were taken up under the guidance of the waste to wealth committee.

|

Used paste fill technology to capitalise on wastes like fly ash, bottom ash and shape them into useful ingredients for cement industry |

|

Commissioning under final stage for our first zinc fumer plant to extract metals from the waste which will open up new streams in our value chain |

|

Conducted tailing dam break analysis at two of the locations to avoid any breaching in the future |

Tailing generated from beneficiation of the ore is stored in Tailing Storage Facilities (TSF) available at all the locations with beneficiation plant. At HZL we have three active tailing storage facilities and all sites have a dedicated TSF manager and TSF committee consisting of the design engineer, operations, construction and environmental staff. All TSFs, as well as associated pipeline and pumping infrastructure, are subject to a regular audit as well as regular inspection.

INITIATIVE

Waste to Wealth - ancillary product plant at Dariba Smelting Complex

A significant 'Waste to Wealth' initiative is the ancillary product plant at DSC to treat residues produced during smelting process leading to in-house production of few key consumables and by-products, in collaboration with the Company's central R&D team. During the year, additional projects were successfully executed including production of copper sulphate and zinc sulphate from PF cake as well as production of potassium antimony tartrate from antimony dust. With this, the gain from ancillary unit during the year was INR 30 crore.

The key initiatives planned for FY 2019 include production of sodium sulphate from RO reject, treatment of slag from silver refinery to produce bismuth oxychloride and production of copper sulphate from copper matte.

FUMER TECHNOLOGY:

FINDING SILVER LINING IN WASTE

CASTING PAVER BLOCKS

USING WASTE