At Hindustan Zinc, air quality management has been integrated into the mining and smelting operation and is compatible with the community and regulatory expectations. We ensure that, at any time and under any usual set of conditions, and at any stage in the mine's life cycle from mine planning, operation to closure, air quality is managed within acceptable levels.

We proactively measure, control and reduce air emissions at each of our sites and are implementing systems and procedures to address any concerns. Through advanced mitigation, measurement and management strategies, we continue to identify, reduce and wherever possible, eliminate any potential impacts to air quality caused by our operational activities.

INITIATIVE

Improving Air Quality & Safety

Rampura Agucha Mine installed Jacon Water Cannon, a water spraying equipment. It improves air quality by suppressing the dust generated on haul roads as well as on freshly blasted stope. As a safety equipment, it loosens the hanging rock pieces through pressure of the water nozzle and is also used in firefighting as its nozzle can rotate 360 degree.

Emissions

Hindustan Zinc Limited is focussed on setting emission reduction and renewable energy targets by aligning with the country's Climate Action Plan under the Paris Agreement.

We are committed to Science Based Target initiative (a global team comprised of UNGC, CDP, WWF and WRI) to set GHG emissions reduction targets in accordance with climate science, i.e., in line with the level of decarbonisation required to keep global temperature increase below 2°C compared to pre-industrial temperatures.

INITIATIVE

Approved SBT targets

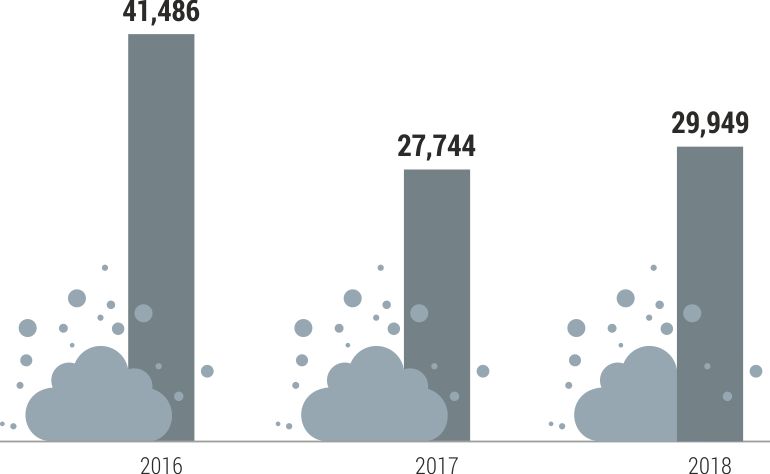

Hindustan Zinc Limited commits to reduce absolute Scopes 1 and 2 GHG emissions 14% by 2026 from a 2016 base year.

Hindustan Zinc Limited also commits to reduce absolute Scope 3 GHG emissions 20% by 2026 from a 2016 base year

Hindustan Zinc participated in CDP (Carbon Disclosure Programme), whereby it calculated and reported greenhouse gas (GHG) inventory, i.e., Scope 1 (process emissions and other direct emissions), Scope 2 (purchased electricity) and Scope 3 (downstream and upstream movement) as defined under the World Business Council for Sustainable Development and World Resource Institute GHG protocols.

We installed an online effluent and emission monitoring system which sends warning alerts to the management when the pollution levels cross the permissible limit. The sensors linked with the departmental software sends an automatic alert message. This system is directly connected to the servers of the State Pollution Control Board. As part of this exercise, we have installed high quality sensors and software to convert accumulated data regarding air and water pollution and send them across to the State Pollution Control Board and Central Pollution Control Board offices.

Our 10 UNFCCC registered projects reduced our carbon footprint by 583,685 MT of CO2 emission per annum while unregistered projects contributed to the reduction of 147,270 tonnes CO2 emissions per annum. New solar projects in the pipeline will further reduce our carbon footprint by 58,000 MT of CO2 emission per annum.

We generated 34.4 MW of power capacity through waste heat recovery from roasters and Steam Turbo Generator (STG) out of which 9.4 MW was from the WHRB project registered under CDM along with 21 TPH LCV boilers for a steam generation project.