MANAGEMENT PROGRAMME

Out of the 6,229 KL/MT of lubricants that Vedanta procures annually, 74% of the requirement originates from HZL. The Rampura Agucha Mines (RAM), being a major location, covers 40% of HZL's lubes consumption. Coupled with the quantity of our lube requirement is the wide range of lubes that we need. Different grades are required for different machines based on user and OEM recommendations, technical specifications and service providers.

This combination of scale and variety resulted in various challenges in procurement and supply chain management of lubricants, such as quality, safety, application management, and cost optimisation.

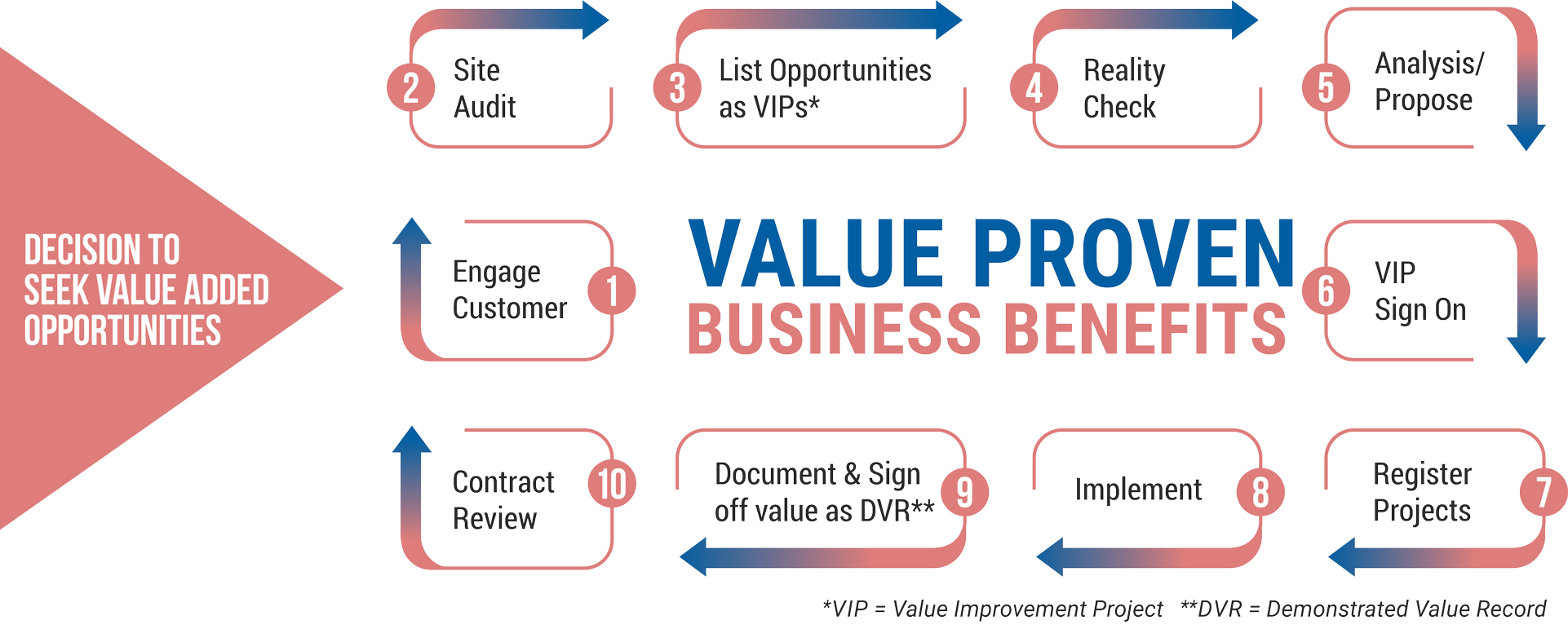

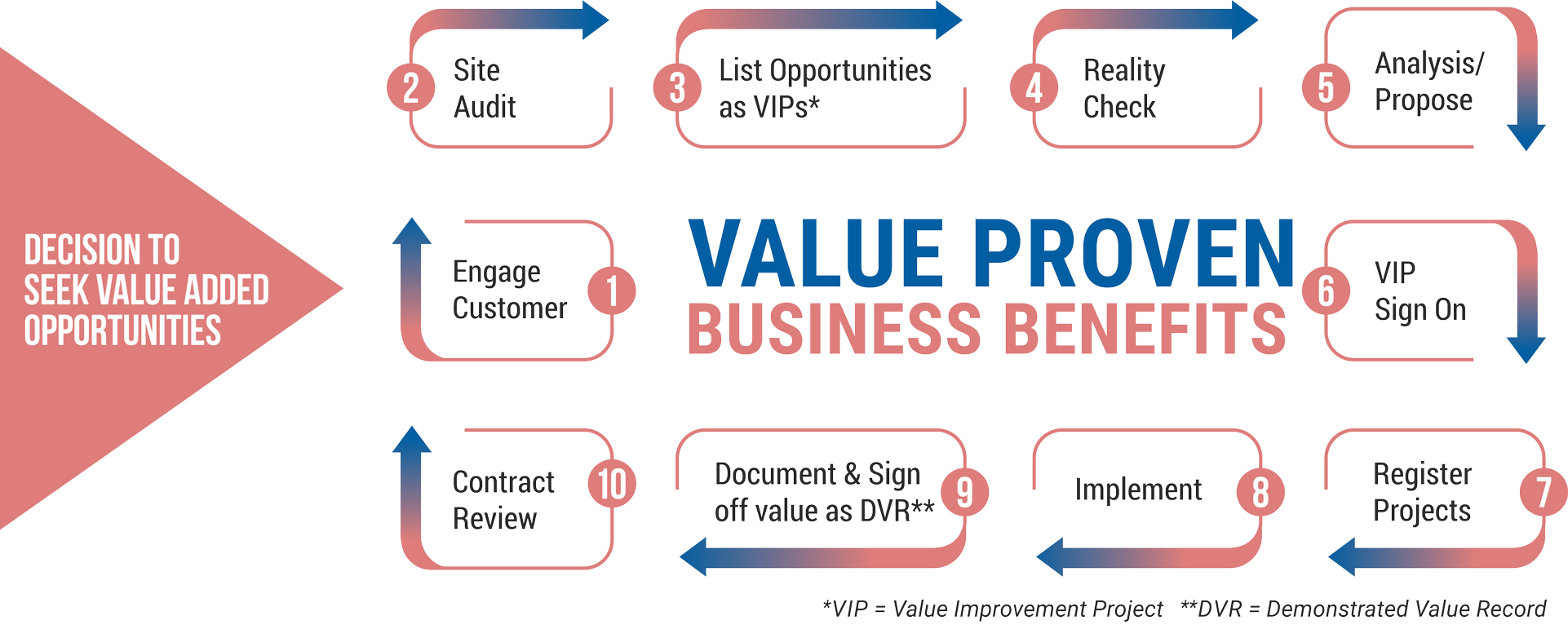

To address these challenges holistically we introduced Total Lubrication Management Programme.

Legacy Lubrication Sourcing Model at RAM

Phase I

Rate Contracting

The annual rate contract with multiple vendors to cater to Hindustan Zinc as well as Vedanta pan India requirements has been finalised for January 2018 to December 2019.

Phase II

Vendor Managed Inventory

Rampura Agucha Mines has provided premises within their plant as per the vendor's specifications and requirements for storing of lubricants. The allocated premises are demarcated by chain-links with facilities for unloading trucks, railway siding, and storage and supply of lubricants to RAM.

The vendor delivers lubricants to the allocated warehouse from the supply points nominated by the vendor. After delivery of the stock to RAM, RAM makes all the necessary documentation for proper accounting of the materials. A joint inspection of the stock on a monthly basis is carried out by the vendor and RAM. The vendor also keeps a track of every lubricant's consumption and their responsible use, ensures reduction in consumption and makes recommendations to reduce lubrication cost.

Switching over to the improved model of procurement of lubricants and streamlining the process led to the following benefits:

| Saving of inventory carrying cost of INR 3 crore bi-monthly considering safety and rollover stock |

| Saving of interest cost by 12% on INR 3 crore, i.e. INR 0.4 crore |

| Reduced stock procurement, holding costs and related manpower cost |

| Transfer of risk and ownership to supplier taking over responsibility for service delivery |

| Reduction in overall consumption of lubricants and guarantee that lubrication tasks will be completed on time and in accordance with approved lubrication schedules |

| Improved systems, procedures and application knowledge for lubrication |

| Better lubrication management using vendor expertise |

| Integrated approach to oil sampling and analysis |

| Exploiting various maintenance tools to further reinforce pro-active maintenance |

| Overall improvement in the standard of lubrication |

| Improvement in equipment reliability (eliminate/increase interval between downtime) |

| Increase in productivity (less equipment downtime) |

| High level of expertise in lubrication application on-site |

| Building a comprehensive plant and equipment lubrication history |